- Connectors

Basic Knowledge of Plating

Plating plays an important role in the function and performance of connectors. It is also used in various forms in our daily life.

The purpose, types, and materials of plating, which may seem familiar but are not well understood in detail, are introduced here.

What is Plating?

Plating is a process of dissolving a metal in a solution and electrochemically depositing it onto a solid surface. This technology can be used to coat or selectively apply another material, typically precious metals onto a metal or plastic base material.

The contact parts of the connector are also plated.

For more information about contacts (terminals), click here.

Everyday items that use plating

- Smartphones, PCs and other electronic devices: Printed wiring (copper plating), LSI packages (gold, nickel, solder plating), chip components (tin plating), connectors (gold, nickel, etc.)

- Automobiles: Various parts such as body parts, bumpers, wheels, emblems, etc. (chrome plating, etc.)

Purpose of plating

Decoration | ・Enhance the appearance |

|---|---|

Protection of the underlying metal | Protect with more corrosion-resistant metals. |

Function Addition | ・Harden the surface (hard chrome plating, etc.) |

Plating Types

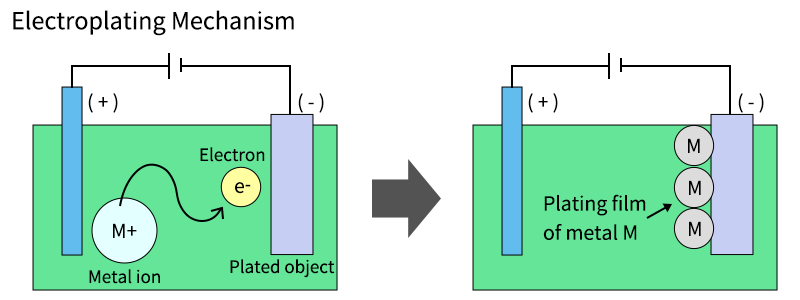

Electroplating

A metal is deposited on the cathode by donating electrons from the outside. Electroplating requires the product to be conductive, and electroplating is not possible on non-conductive materials.

Most Kyocera connectors are plated using electroplating.

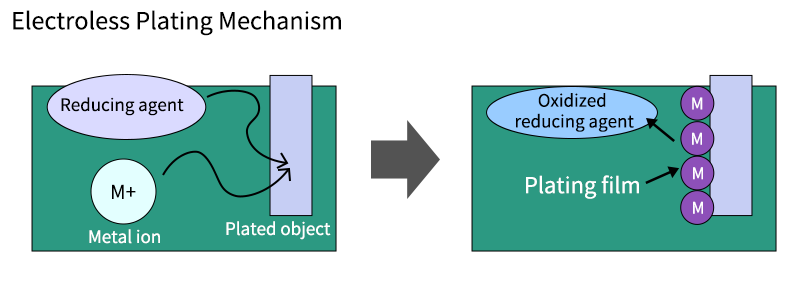

Electroless plating

Metals are deposited by the donation of electrons by the reducing agent in the plating solution. In electroless plating, plating is applied simply by immersion, but depending on the material to be plated, some materials can be plated directly and others, such as resins, cannot be plated without a catalyst.

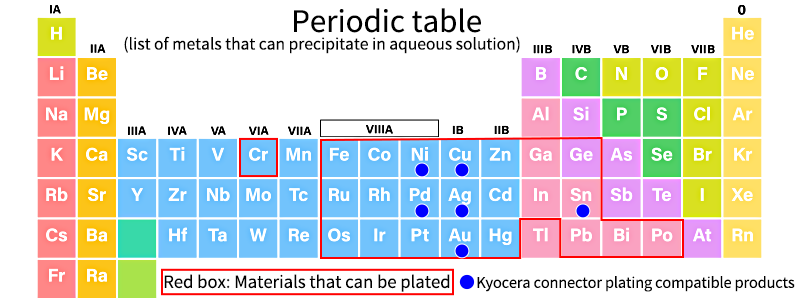

Plating Materials

- If alloyed, elements other than those shown below can also be precipitated.

(Example: Ni-P, Ni-B, Ni-W or Mo, Cd-Te, Cu-In-Ga-Se etc.) - In addition, if non-aqueous systems (organic solvents, molten salts, etc.) are used, metals such as Mg and Al can also be plated.

Why Do Connectors Need Plating?

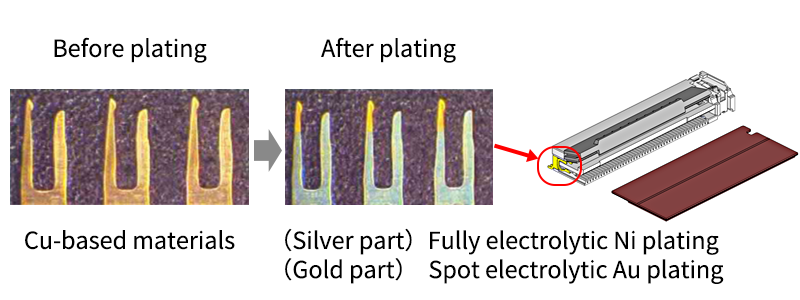

To give copper-based connectors the properties of other metals (corrosion resistance, solderability, etc.).

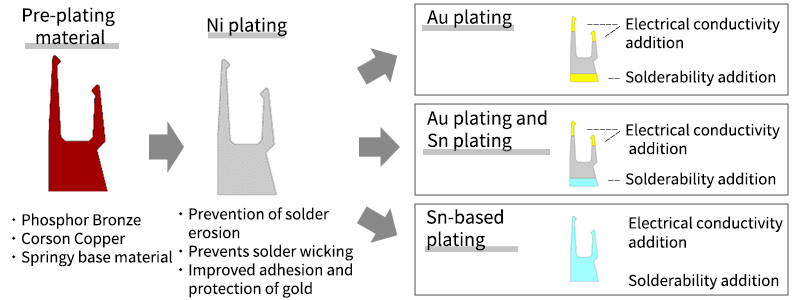

Types and functions of plating used for connectors

Summary

The reason for plating the contacts of connectors is to give them functionality.

Function of plating in connectors

By using "Ni base + Au plating" or "Ni base + Sn-based plating" for Cu-based material, it is possible to create contacts that meet all of the functions required of connectors, such as solder wettability, corrosion resistance, low contact resistance, and electrical conductivity.

Comprehension Test

Q1. Which of the following plating is mainly used on Kyocera connectors?

(1)Electroplating (2)Substitution Plating (3)Hot-Dip Plating

Q2. What is the purpose of Au (gold) plating on connector terminals?

(1)Harden the surface (2)Reflecting light (3)Adding electrical conductivity

Answer (Click to Check)

- A1. (1)Electroplating

- A2. (3)Adding electrical conductivity

List of Connector Trivia Articles

vol.5 Evaluation Test (Basics)

vol.6 Evaluation Tests (Special Edition)

vol.7 The History of Kyocera's FPC/FFC Connectors

vol.8 Evolution of FPC/FFC Connectors

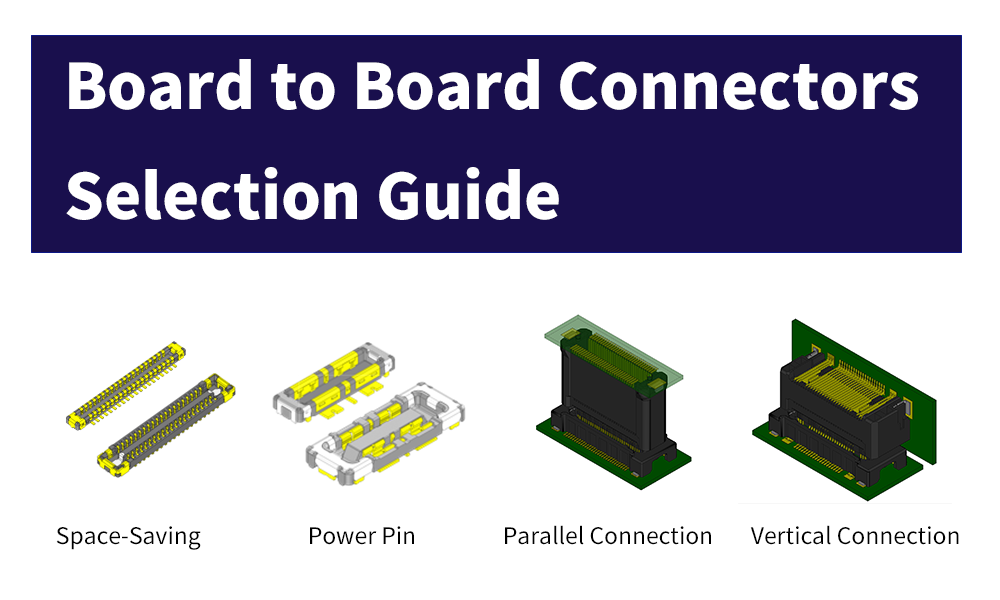

vol.9 Basic Knowledge of Board to Board Connectors

vol.10 Learn more about Board to Board Connectors ~Various Features~

vol.11 Basic Knowledge of Plating

Related Links

The Important Information/Disclaimer is incorporated in the catalog and/or this page by reference and should be reviewed in full before placing any order or inquiry.