- Connectors

Evaluation Tests (Special Edition) -Connector Trivia vol.6-

Introducing some special evaluation tests for connectors.

Overview

To verify the reliability of connectors, special evaluation tests are performed depending on the installed equipment and product specifications.

Examples of special evaluation tests:

Test Items and Objectives

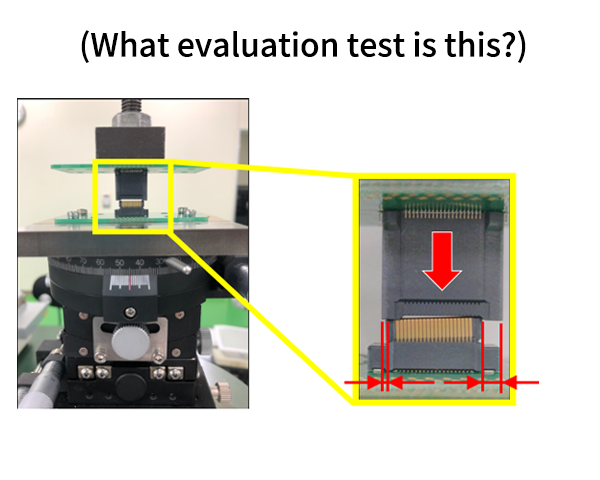

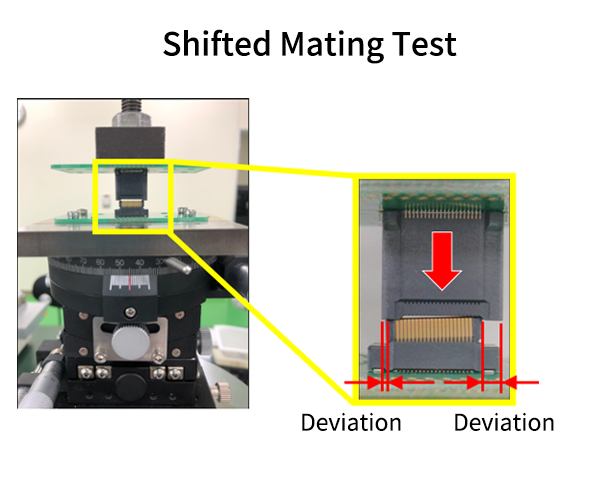

1. Shifted Mating Test

Check the fitability in consideration of the variation of mating in board to board connectors.

2. Fretting Corrosion Test

When carrying a mobile device, surface damage (wear) occurs due to repeated small vibrations. Contact reliability is checked to meet such situations.

3. Drop Test

Check the performance of parts when drop impact is applied. It is intended for use with smartphones and wearable devices that are accidentally dropped.

4. Aging Test

Even if the fitted FPC/FFC can move due to the structure of the device on which the connector is mounted, check that the contact is made correctly.

Keywords

What is Aging?

Aging tests, which are derived from the "the condition of growing old or passing through time" are also used to test machines and electronic equipment before they are shipped, run-in tests before they are put into service, and tests to evaluate durability and durability under prolonged load.

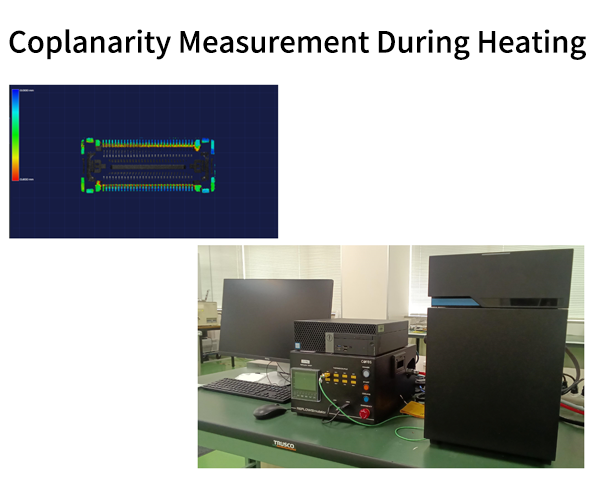

5. Coplanarity Measurement During Heating

Check the behavior of the contact tail (landing surface) position against the heat during reflow.

6. Combined Vibration Test

In addition to vibration when the car is running, resistance to repeated fluctuations in low temperature (shrinkage) and high temperature (expansion) is checked.

7. Dust Test

For parts installed in cars, check if the parts function properly even in a dusty environment.

8. Environmental Test

Deterioration caused by the natural environment is confirmed by irradiating a light source approximating sunlight.

9. Solder Peeling Strength Test

Check whether there is a problem with the soldering by the force when disengaging the mating or operating the connector.

10. Waterproofing Test

Check the waterproofing effect when installed on equipment used outdoors.

Comprehension Test

Q. In order to confirm the reliability of the connector, special evaluation tests are performed depending on the installed equipment and product specifications. What kind of test is shown in the image on the right?

Please choose the answer from below.

- Shifted Mating Test

- Fretting Corrosion Test

- Drop Test

- Aging Test

- Coplanarity Measurement During Heating

- Combined Vibration Test

- Dust Test

- Environmental Test

- Solder Peeling Strength Test

- Waterproofing Test

Answer (Click to Check)

- A. 1. Shifted Mating Test: Check the mating performance in consideration of the variation of mating work in the board to board connectors.

List of Connector Trivia Articles

vol.5 Evaluation Test (Basics)

vol.6 Evaluation Tests (Special Edition)

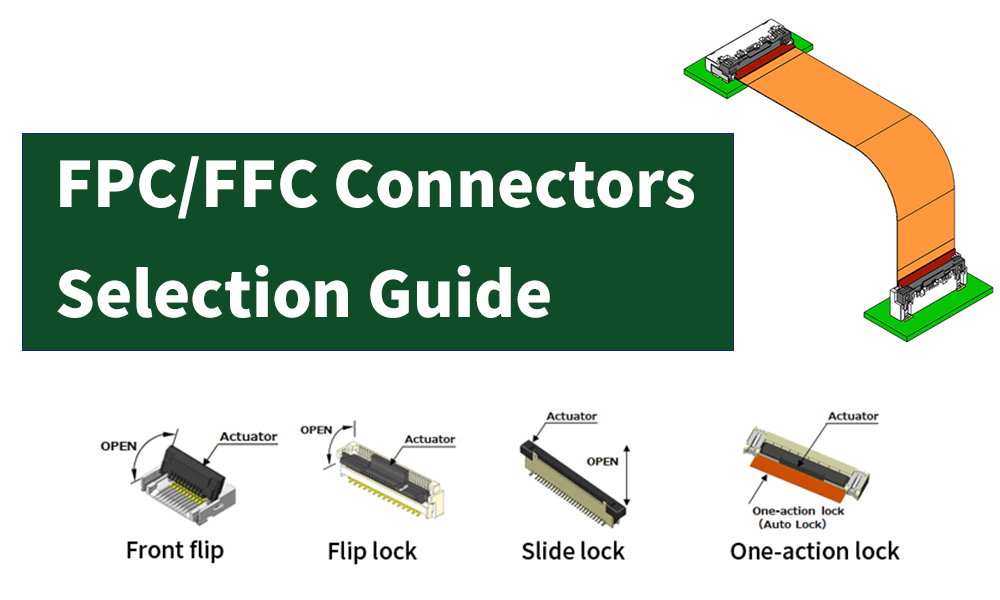

vol.7 The History of Kyocera's FPC/FFC Connectors

vol.8 Evolution of FPC/FFC Connectors

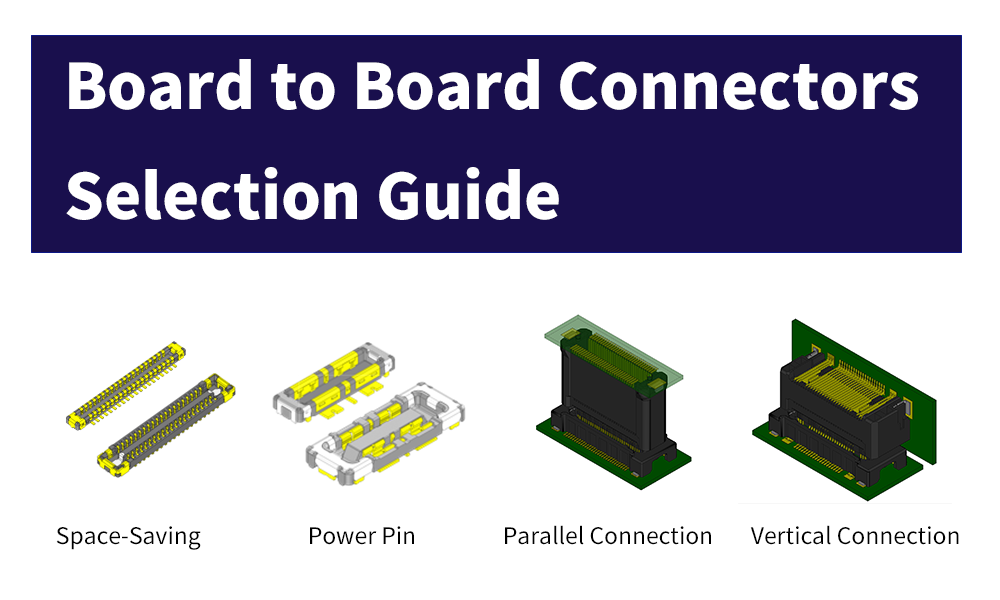

vol.9 Basic Knowledge of Board to Board Connectors

vol.10 Learn more about Board to Board Connectors ~Various Features~

vol.11 Basic Knowledge of Plating

Connectors Top Page