- Connectors

Insulator - Connector Trivia vol.3 -

An overview of insulators, one of the components that make up a connector, and its materials.

What is an Insulator, and From What Materials is it Made?

An insulator is a component that forms the entire connector and and protects the contacts (wires).

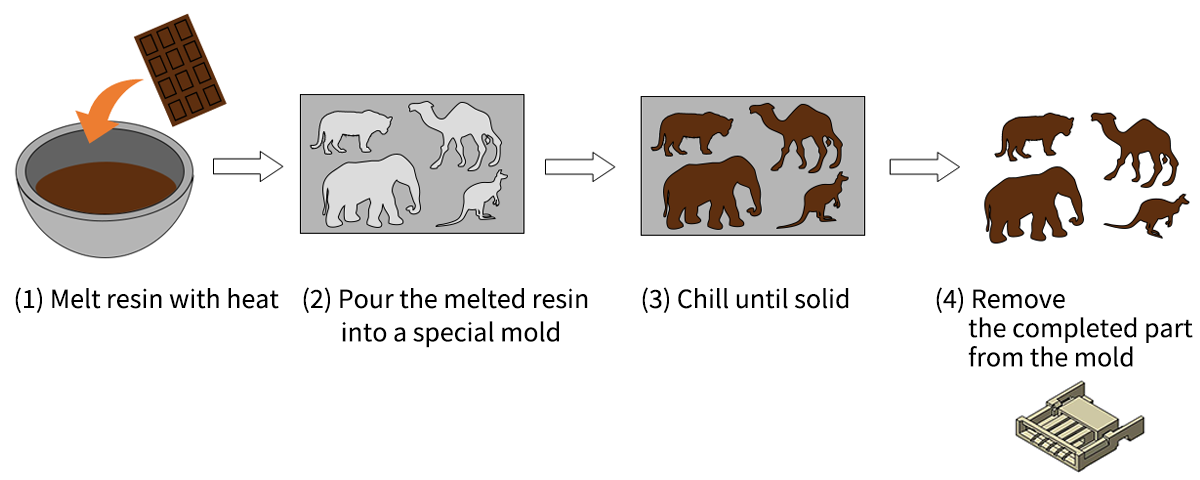

It is mainly made of resin and placed in a special mold just like melting chocolate and putting it in a mold to make a shape.

Types of Resins Used in Insulators

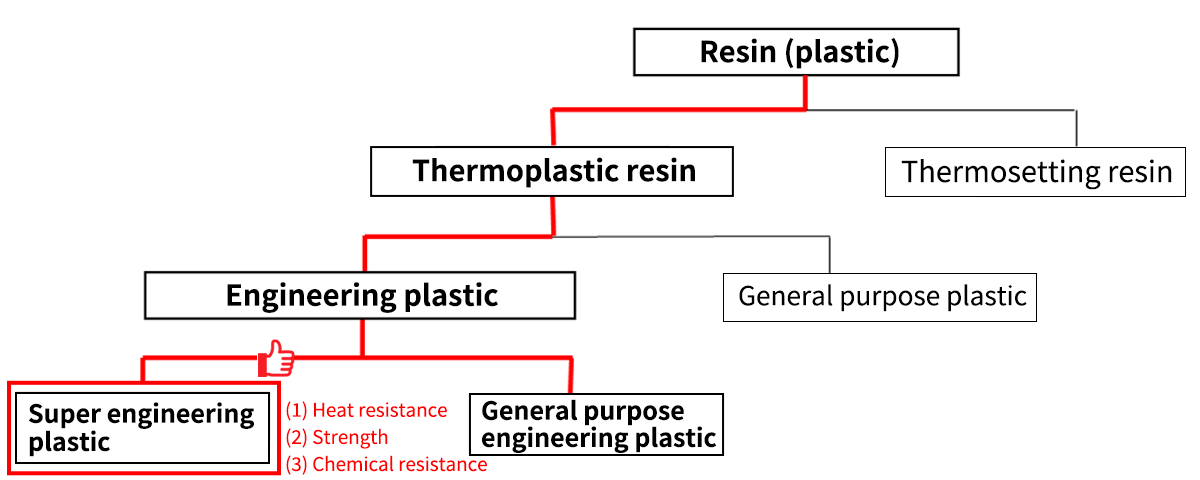

There are many types of resins used as materials.

The main types are thermoplastics and thermosets, and the connectors are made of thermoplastic engineering plastics.

There are two types of engineering plastics; super engineering plastics and general purpose engineering plastics. Recently, the number of surface mount (SMT) type connectors is increasing, and we are mainly using super engineering plastics that excel in three functions: (1) heat resistance, (2) strength, and (3) chemical resistance.

Keywords The Official Mascot of Kyocera’s Electronic Components Division: Eletan

The Official Mascot of Kyocera’s Electronic Components Division: Eletan

Click here to learn more about Eletan

What is an engineering plastic?

A high-performance plastic with excellent strength and heat resistance.

Types of Engineering Plastic Commonly Used in Connectors

| Name | Description | |

|---|---|---|

| Super engineering plastic | LCP : Liquid Crystal Polymer | Excellent heat resistance and allows the resin to flow easily through narrow gaps, making it suitable for molding insulators for complex shapes. Other characteristics required for connectors, such as stiffness, elasticity, chemical resistance, and dimensional stability, are all at a high level, but it is more expensive than other resins. |

| PPS : Polyphenylene Sulfide | Excellent heat resistance and, like LCP, flows well, allowing the resin to flow even in complex shapes. It also has excellent flame resistance, mechanical characteristics, dimensional stability, and chemical resistance, and is extremely hard. | |

| PA Polyamide (Nylon) | Excellent in heat resistance and toughness, but also easily absorbs moisture. Like LCP and PPS, it can handle complex shapes, but it is used for parts with relatively simple shapes because the resin does not penetrate tight spaces. | |

| General purpose engineering plastic | PBT : Polybutylene Terephthalate | Used to make relatively large insulators, such as through hole types, that do not require reflow heat resistance. Glass-reinforced PBTs have higher heat resistance and strength, but without glass, they have slightly lower heat resistance. It costs about half that of LCP and is inexpensive. |

Comprehension Test

Q1. There are many types of resins used in insulators, but they can be broadly divided into thermoplastics and thermosets.

Which resin is used for connectors?

(1) Thermoplastic resin (2) Thermosetting resin

Q2. Which engineering plastic is NOT used in connectors?

(1) Liquid Crystal Polymer (2) Polypropylene (3) Polyamide (4) Polybutylene terephthalate

Answer (Click to Check)

- A1. (1) A2. (2): Polypropylene, also called PP, is widely used in everyday life such as household goods and packaging.

List of Connector Trivia Articles

vol.3 Insulator

vol.5 Evaluation Test (Basics)

vol.6 Evaluation Test (Special Edition)

vol.7 The History of Kyocera's FPC/FFC Connectors

vol.8 Evolution of FPC/FFC Connectors

vol.9 Basic Knowledge of Board to Board Connectors

vol.10 Learn more about Board to Board Connectors ~Various Features~

vol.11 Basic Knowledge of Plating