- Connectors

Contact (Terminal) - Connector Trivia vol.4 -

An overview of metal contacts (or terminals) and their materials.

What is a Contact and its Materials?

Contacts are metal parts that allow connectors to have contact and energizing functions.

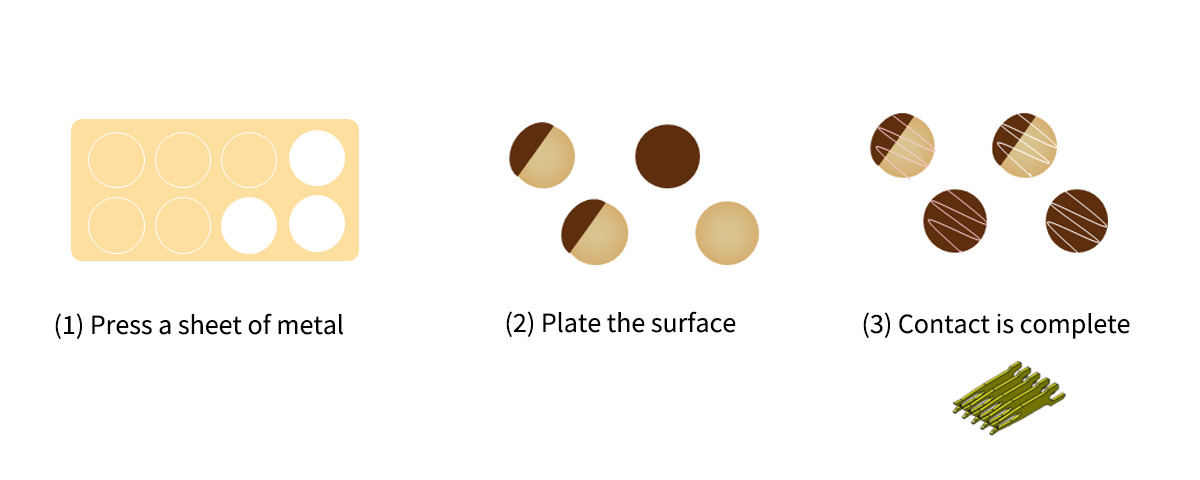

A metal plate is pressed using a mold, and then sheared and bent to form a shape. The parts are then plated to complete the contact.

It is like cutting out the dough of a stretched cookie and pour chocolate over it.

Types of Metal Used in Contacts

Copper alloy with low electrical resistivity are used as the metal material in contacts.

Despite its good electrical characteristics, copper has mechanical weaknesses, such as very low tensile strength and softness, so we use a copper alloy with excellent spring characteristics for contacts where contact stability is important.

Use the following materials according to the specifications required for the connector.

| Metal Material | Description |

|---|---|

| Phosphor bronze | A copper alloy made by blending copper (Cu) with phosphorus (P) and tin (Sn), which has excellent mechanical characteristics and is a standard material. It is also easy to handle. |

| Brass | A copper alloy containing copper (Cu) and zinc (Zn). It is a cheap material that is widely used in consumer and automotive applications. |

| Corson copper | A copper alloy made of copper (Cu) blended with nickel (Ni) and silicon (Si), which is widely used in the automotive market as a high-conductivity, high-heat-resistant material. |

| Beryllium copper | Used as a high-strength copper alloy material that contains several percent of beryllium (Be) in copper (Cu), but the use of beryllium is restricted in some cases due to its toxicity. |

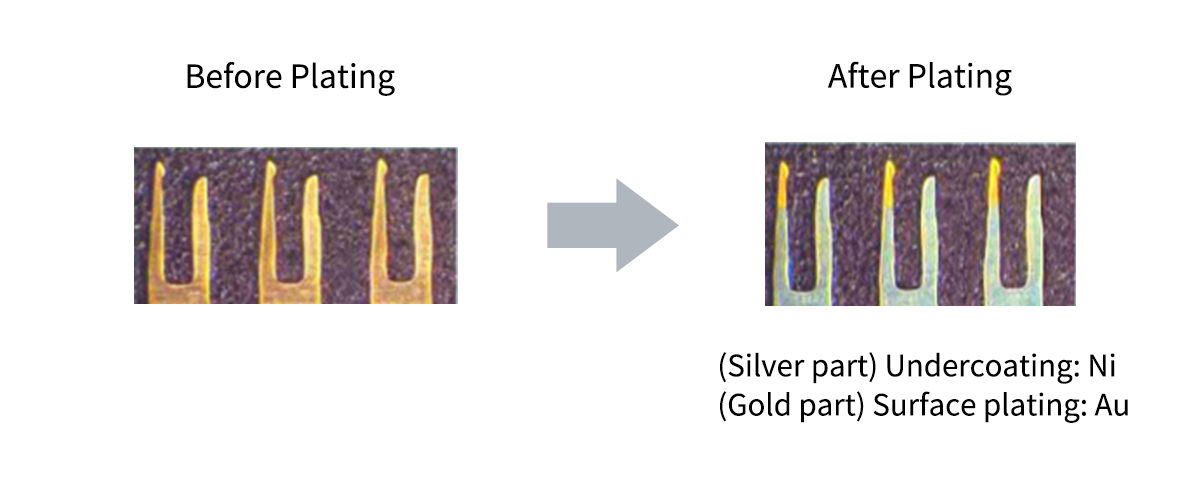

Types of Plating Used for Contacts

The contact area is plated to prevent oxidation and corrosion of the contact area, to retain electrical characteristics, and to make it easier for customers to solder the connection area.

Keywords The Official Mascot of Kyocera’s Electronic Components Division: Eletan

The Official Mascot of Kyocera’s Electronic Components Division: Eletan

Click here to learn more about Eletan

What is plating?

The application of a thin film of metal to the surface of a metal or non-metal material.

Use the following materials according to the specifications required for the connector.

Plating material | Surface / Undercoat | Description |

|---|---|---|

Tin (Sn) | Surface | Electrical characteristics are inferior to those of gold or silver, but still good. |

Gold (Au) | Excellent electrical characteristics and corrosion resistance but is expensive. | |

Silver (Ag) | Excellent electrical properties but poor corrosion resistance. | |

Palladium (Pd) | Surface and undercoat | Hard and excellent corrosion resistance. It is used to reduce the amount of gold used. |

Nickel (Ni) | Undercoat | Hard and good adhision. |

Copper (Cu) | Excellent adhesion. Nickel is now the mainstream. |

Comprehension Test

Q. Complete the following paragraph by filling in (a) to (f) using the keywords below.

(1) Gold (2) Silver (3) Tin (4) Nickel (5) Adhesion (6) Corrosion resistance

Tin (Sn): Electrical characteristics are inferior to those of gold or ( a ) but good. Less corrosion-resistant but relatively inexpensive.

Gold (Au): Excellent electrical characteristics and corrosion resistance but is expensive.

Silver (Ag): Excellent electrical characteristics but poor corrosion resistance. Expensive compared to ( b ), but inexpensive compared to gold.

Palladium (Pd): Hard and has excellent ( c ) characteristics. Used to reduce the amount of ( d ).

Nickel (Ni): Hard and excellent in ( e ) characteristics.

Copper (Cu): Excellent adhesion. Today, ( f ) is the mainstream.

Answer (Click to Check)

- A. a.(2) Silver b.(3) Tin c.(6) Corrosion resistance d.(1) Gold e.(5) Adhesion f.(4) Nickel

List of Connector Trivia Articles

vol.4 Contact (Terminal)

vol.5 Evaluation Test (Basics)

vol.6 Evaluation Test (Special Edition)

vol.7 The History of Kyocera's FPC/FFC Connectors

vol.8 Evolution of FPC/FFC Connectors

vol.9 Basic Knowledge of Board to Board Connectors

vol.10 Learn more about Board to Board Connectors ~Various Features~

vol.11 Basic Knowledge of Plating