Printed circuit board cropping

When cropping a printed wiring board after mounting capacitors and other components on it, make sure not to

apply bending or twisting stress to the board.

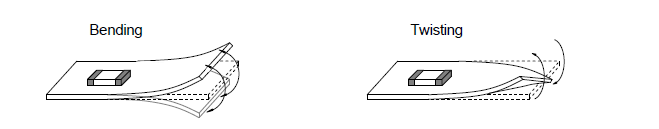

When cropping, causing a bending or a twisting deformation illustrated in the following figure to a printed

wiring board may cause cracks in capacitors.

Stress created during substrate cropping should not influence to the capacitor as far as possible.

Check the cropping method applied to printed circuit boards in advance.

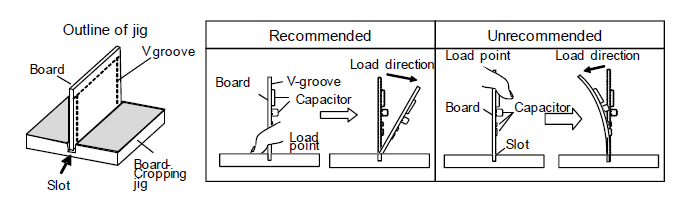

Printed circuit board cropping should be carried out using a board cropping jig shown in the following figure

or a board cropping apparatus to prevent inducing mechanical stress on the board.

Example of a board cropping jig

Recommended example: The board should be pushed from the back side, close to the cropping jig so that the

board is not bent and the stress applied to the capacitor is compressive.

Non-recommended example: If the pushing point is far from the cropping jig and the pushing direction is from

the front side of the board, large tensile stress is applied to the capacitor, which may cause cracks in the

capacitor.

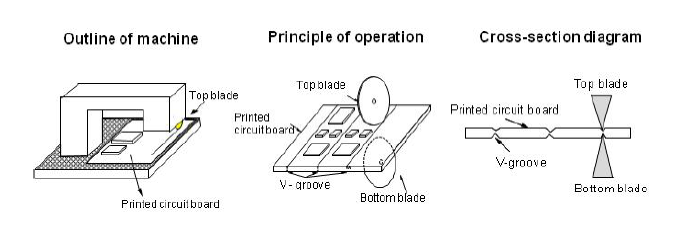

Example of a board cropping machine

An outline of a printed circuit board cropping machine is shown below. The top and bottom blades are aligned

with one another along the lines with the V-grooves on printed circuit board when cropping the board.

The misalignment of the blade position between top and bottom, right and left, or back and forth blades may

cause a crack in the capacitor.

| Recommended | Unrecommended | ||

|---|---|---|---|

|

Top-bottom misalignment |

Left-right misalignment |

Front-rear misalignment |

|

|

|

|

Safety Application Guide for Multilayer Ceramic Chip Capacitors All Lists