- Capacitors

Developer Interview - Behind the Development of Kyocera’s EIA0201 Model 10μF Product MLCC -

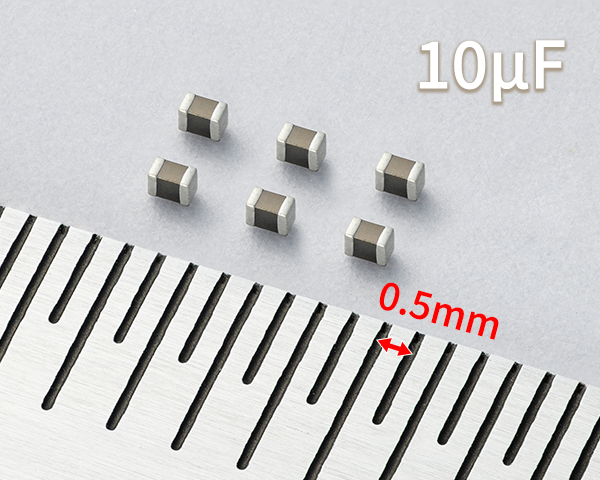

Kyocera has pioneered the world's first EIA0201 size (0.6 x 0.3mm) MLCC with an industry-leading capacitance class* of 10μF.

We interviewed the development project team about the untold stories behind the creation of the new product and what motivated them to keep pushing forward.

*For EIA0201 size MLCCs. As of March 2023. According to Kyocera research.

―Please provide an overview of the new EIA0201 size 10μF MLCC

What we have developed is an MLCC (Multilayer Ceramic Chip Capacitor) with the industry's highest capacity class* for EIA0201 size (0.6 x 0.3 mm) and 10 μF capacitance.

As smartphones and wearable devices become more sophisticated, the capacity of MLCCs required for electronic devices is increasing, and the number of components installed is increasing year by year. On the other hand, devices tend to be smaller in size. Against this background, there is strong demand from the market for miniaturization and higher capacity per MLCC.

The evolution toward smaller size and higher capacitance has resulted in the development of EIA0603 size (1.6mm x 0.8mm) for 10μF capacitors, and EIA0402 (1.0mm x 0.5mm) since the 2000s. However, the EIA0201 (0.6mm x 0.3mm) 10μF capacitor presented an extremely high level of technical difficulty and had not been commercialized until now.

In March 2023, Kyocera developed a 10μF EIA0201 size capacitor (0.6mm x 0.3mm) through its proprietary cutting-edge elemental technologies and new manufacturing methods aimed at maximizing capacitance. This marked the world's first press release announcing such an achievement.

Mass production has already commenced, and the product has been adopted by multiple customers.

*For EIA0201 size MLCCs. As of March 2023. According to Kyocera research.

―What difficulties did you encounter during development, and how did you overcome them?

In order to achieve EIA0201 size 10μF, it is necessary to stack several hundred layers of dielectric layers and internal electrode layers with a thickness of 0.5μm or less. Even a single point of conduction between layers could result in a short circuit (failure), making it challenging to ensure the stability of quality, reliability, and productivity simply by making layers thinner.

To achieve smaller size, higher capacitance, and greater reliability in MLCCs, it is essential to develop material and process technologies, including dielectric materials, sheet forming, internal electrode materials, printing, lamination, and firing. Additionally, developing analytical technologies such as short circuit analysis and microstructure analysis is necessary to identify defect causes and provide feedback. Effectively balancing these two key areas is crucial for accelerating development speed and improving the precision of problem-solving.

To achieve a 0.1μm thin-film coating, we conducted countless fundamental evaluations on a daily basis. These were painstaking and tedious, but also crucial to ensuring quality and reliability. By repeating these evaluations, we identified and resolved challenges, established new standards, and enhanced the accuracy of these standards, creating a system that prevents defects from occurring. This is how we have overcome technical challenges.

|

|

|

Please note that the information regarding employee affiliations and department names is current as of the time of the interview.

―What is the composition of the project team?

The project team consists of eight members selected from three departments: Development, Production Engineering, and Manufacturing. This was a cross-departmental development effort.

In this project, the project members played a central role in the development of new products. This collaboration involved related departments and the “team strength” that transcended the boundaries of departments.

- Development Department: New product design, creation of elemental technologies, and development of analytical techniques.

- Production Engineering Department: Development of new methods and start-up of facilities.

- Manufacturing Department: Ensuring quality improvement and production stabilization.

As described above, given the distinct roles of the three departments, it is to be expected that the various engineers assembled will all have different opinions, perspectives, and skills. As a result, we sometimes clashed with each other to solve problems. However, we were all committed to being the first in the world to release a cutting-edge product. Toward this goal, we were able to flexibly accept opinions and come together in unity by firmly keeping in mind our common belief that we should leverage our collective knowledge and make possible what cannot be done.

―Why did you decide to proceed with this development?

Kyocera's capacitors are characterized by their compact design and high capacitance. We started this development with a strong desire not to lose to other companies in this field.

As mentioned earlier, many years have passed since the EIA0402 10μF was developed, and it was a well-known fact that the development of the EIA0201 10μF product was technically difficult.

That's why we wanted to boldly take on the challenge and open up new markets.

We believe that by leading the industry through these development activities, we can put Kyocera's Management Rationale “To contribute to the advancement of society and humankind” into practice. That is why we proceeded with development.

―Where will this product be used in the future?

While the products developed using this technology are currently intended for the telecommunications market, we plan to expand into the automotive and semiconductor markets in the future.

We also intend to establish next-generation ultra-thin layer technologies for dielectric and internal electrode layers. Furthermore, we will take on the challenge of developing cutting-edge products that are of high quality and can withstand high temperatures and electric fields.

We strongly believe that MLCCs developed in this way—even as passive components—can transform devices, and that these devices can transform systems, contributing to new value and more exciting society and world.

Kyocera will continue to take on the challenge of developing new MLCC technologies and products, thereby leading the industry

and implementing our Management Rationale “To contribute to the advancement of society and humankind.”

Feature Page

The Road to Thinner MLCCs and New Product Development

Related Links

Click Here for All MLCC Products

The Important Information/Disclaimer is incorporated in the catalog and/or this page by reference and should be reviewed in full before placing any order or inquiry.