- KAVX Products

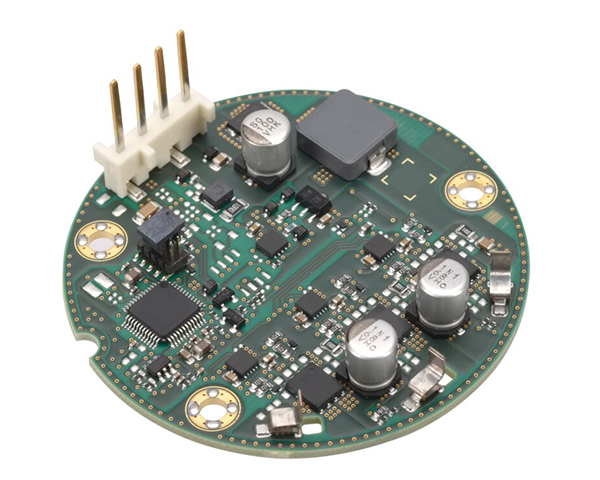

Customer-Specific Power Modules for Electronic Water Pumps

New technology enables high efficiency and long service life.

Overview

KYOCERA AVX Components in Salzburg (Austria) specialize in customer-specific intelligent power modules and have been dedicated for over 30 years to the development and production of control systems for electric water pumps.

Control systems from KYOCERA AVX Salzburg are the heart of electric water pumps that, independent of the vehicle drive, adjust their own rotational speed to the cooling requirement and so reach the desired operating temperature efficiently and quickly.

The Latest Generation Offers High Effectiveness and Long Service Life in Different Applications

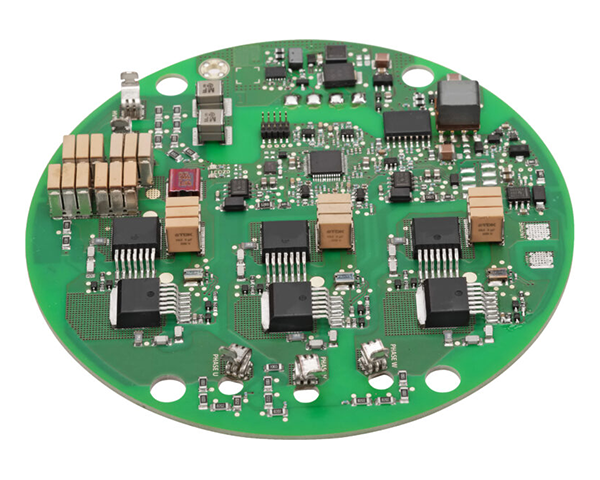

Optimized in several product generations, the electric water pumps with the latest product generation from KYOCERA AVX achieve a very high efficiency of > 95%.

In that way, the electric range in vehicles is increased or the fuel consumption is reduced. The long service life of the hardware reaches 8,000h to 30,000h (depending in the temperature load profile). The practically silent operation permits use in hybrid, electric and fuel-cell vehicles.

Especially in the electric and fuel-cell vehicles, electric water pumps are used for the cooling of various components. These include, for example, electric motor, DC/DC converter and the battery, as well as for the air conditioning of the passenger compartment as part of the air-conditioning control system.

Customer-Specific Design With the Help of State-of-the-Art Simulation Provides Advantages for System Integration

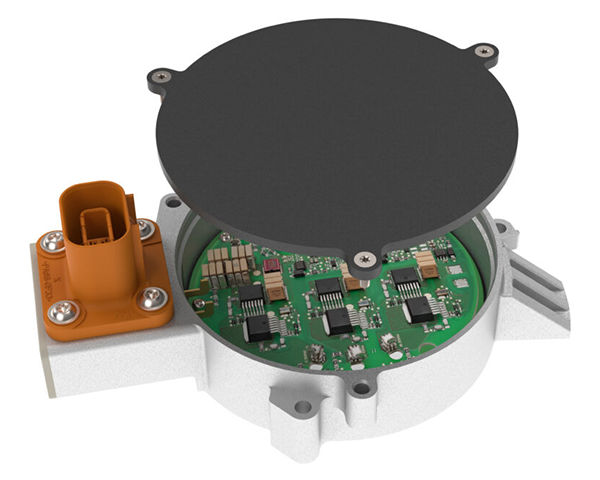

A customer-specific control system from KYOCERA AVX (Salzburg) provides significant advantages for integration into the electric motor and into the existing installation The modules contain all the necessary components for controlling the electric water pump. Its design is adapted to the smallest installation space requirements through the selection of the electrical components and mechanical connecting elements and perfectly matched to the respective application.

The comprehensive know-how of several product generations is used via sophisticated thermal and mechanical simulation. Every control system meets the requirement of a perfectly coordinated solution regarding space, reliability, manufacturability, and cost efficiency. This is also contributed to by the specially developed contact and connection elements that enable optimum connection to the external plug and, besides the mechanical reliability, also provide an important cost advantage.

Modular Components and Proven Supply Chain Allow Flexibility and Short Development Times

Increasingly shorter development times in the automotive industry are realized through developed platforms for hardware and software solutions.

Hence, it is possible to make first prototypes available within only a few weeks and to successfully implement a closely coordinated project schedule up to series production. All platforms can at any time be adjusted to the needs of other applications and automotive manufacturers.

That applies to the power (30W to 10kW), to the on-board voltage (12V to 810V), and to the required communication (PWM, LIN, CAN) with the control unit.

| Platform | |||||

|---|---|---|---|---|---|

| Voltage | 12V | 24V | 48V | 470V | 810V |

| Power | 20W to 600W | 100W to 1.2kW | 200W to 7kW | 700W to 7kW | 700W to 10kW |

| Temperature | -40℃ to +150℃ | ||||

| Substrate | FR4-PCB or thick layer ceramics | ||||

| Service Life | 8,000h to 30,000h | ||||

| Communication | PWM, LIN, CAN | ||||

Due to the increasing complexity of the modular solutions, the supply chain is of great importance. Our supplier basis is based on professional supplier risk management and has grown to be a powerful network.

Also, in times of allocation we were together able to maintain deliveries in the best possible way. In this case, both direct contact with the component suppliers and the possibilities of second source components played an important role.

For the greatest possible flexibility, we rely on the use of microcontroller firmware independent of manufacturers, to act quickly and, as far as possible, independent of the market conditions.

Functions such as error handling, diagnosis, loading of the software via on-board-diagnosis (OBD) and a very efficient field-oriented control algorithm are integrated into this special software. To support the topics of functional safety and cyber security we have, furthermore, developed our own real-time operating system.

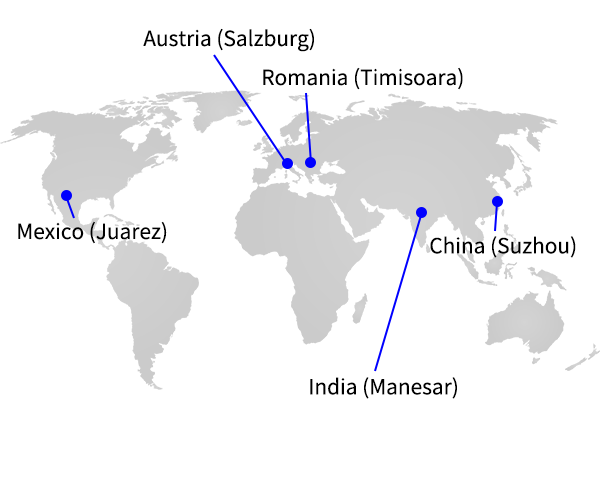

International Production Sites Enable Sustainability and Profitability of the Projects

As companies of the international Kyocera AVX Group we have international production sites at our disposal. With our teams in Europe (Salzburg + Timisoara), China (Suzhou), Mexico (Juarez), India (Manesar) and in future also in Japan, we follow the market and hence our customers. They appreciate the advantage of local, hence resource-saving production.

Sustainability and the associated issue of carbon footprint have a high priority in our philosophy and are considered in every project from development, for the selection of the series suppliers but also for the determination of the production sites. Our customers benefit, moreover, from the logistical advantages that make an important contribution to the profitability.

Proven Technologies and Processes for Successful Implementation of Complex Control Systems

In the automotive industry, the integration of electronic control systems is increasing rapidly. This presents original equipment manufacturers and suppliers, in the case of system design, with ever new challenges regarding improved reliability with a simultaneously reduced installation space.

KYOCERA AVX (Salzburg) are, thanks to extensive experience in this field, able to successfully bring customized projects, with appropriate development competence including the associated technology and manufacturing capacity, into production.