- KAVX Products

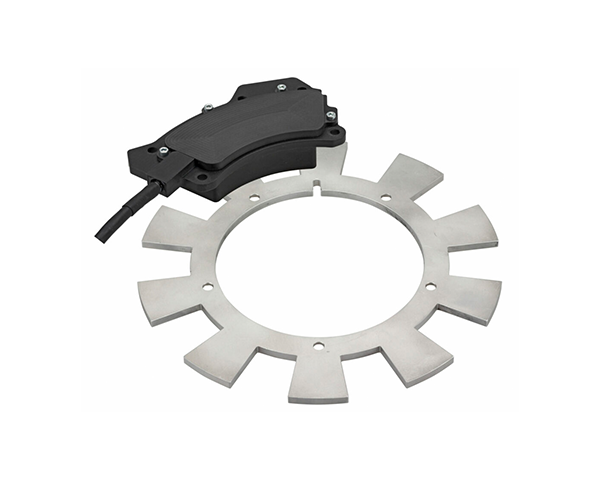

Rotor Position Sensor – Electric Motors

Introducing an inductive high speed rotor position sensor (SPINpad sensor).

Overview

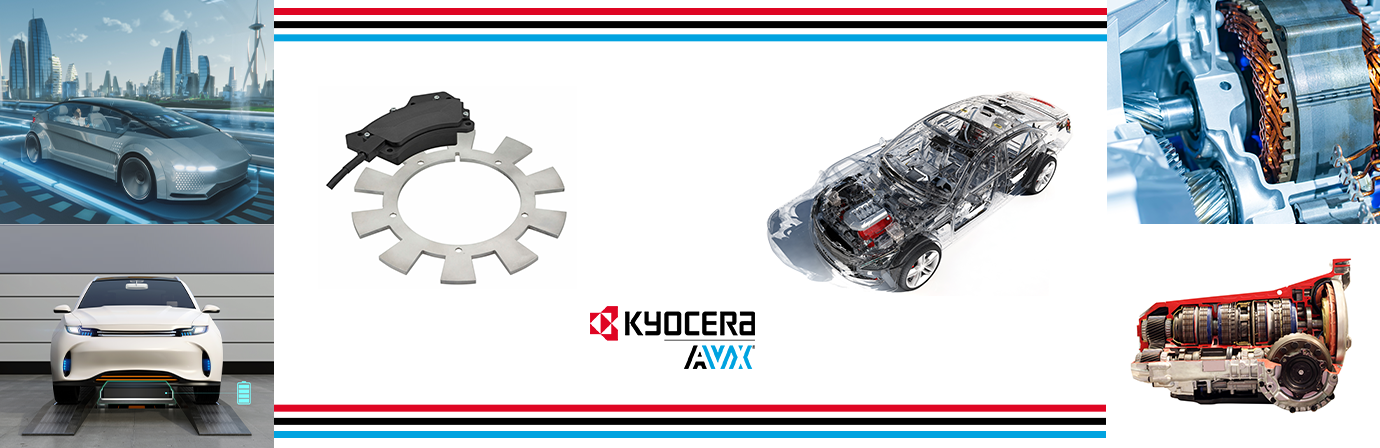

A combination of high accuracy and fast response time is required for rotor position sensors in the electric motors of hybrid or electric vehicles. This allows the control unit to drive the motor optimally, and leads to a reduction in energy consumption and an increased range of the vehicle.

KYOCERA AVX has developed a new high speed position sensor to meet these requirements. First prototypes of this new sensor have demonstrated market leading performance. This technology can be used in other applications where accuracy and response times are critical (for example, electric power steering), and is also capable of making an additional velocity measurement, which could be used in active suspension systems.

The basic structure of the SPINpad sensor is similar to KYOCERA AVX‘s mature and proven Autopad® technology. However, the SPINpad sensor uses one coil as a transmit coil and two coils as receive coils.

Features

- Flexible designs, can be matched to motor pole-pairs giving positional accuracy

< 0.5deg electrical - Different targets available

- Signal immediately after power on

- High speed up to 100,000 rpm

- Ready for ASIL C (D) or with redundant measurement ASIL D (D)

- Immune to low frequency magnetic fields

- Small package size, flat design

- Temperature range: -40℃ to 160℃

Typical applications

- Traction Motors for any application (e.g. BEV, PHEV, HEV and MHEV or industrial applications)

- Electric Compressor

- Steer by Wire

- Electric Turbocharger/Supercharger

- Brake Booster