AMA10EB045 1.계획중

Schottky barrier diodes are not PN junctions, but diodes that utilize potential barriers between semiconductor materials and metal electrodes, e.g., Schottky barrier. They have lower forward voltage (VF) characteristics and shorter reverse recovery time (trr) than typical PN junction diodes, making them suitable for switching operation. However, the reverse current (IR) is larger than that of conventional PN diodes.

애플리케이션

- 전원 장치

- 산업기기

- 자동차 (인포테인먼트)

- 자동차 (운전 / 안전 장비)

사양

| 시리즈 | MA |

|---|---|

| AEC-Q |

AEC-Q101 |

| Outline |

DO-221BC |

| VRRM [V] | 45V |

| Io [A] | 10.0A |

| IFSM [A] | 200.0A |

| IR [mA] | 0.600mA |

| VFM [V] | 0.54V |

| @IFM [A] | 10.0A |

| 사용온도범위 | -55℃ ~ 150℃ |

| Rth(j-c) [°C/W] | 4 (j-l)°C/W |

| 포장 | Reel |

| Quantity per Package | 3000 |

| 제품 질량 | 0.040g |

포장 사양

| 포장 | Reel |

|---|---|

| Quantity per Package | 3000 |

| 제품 질량 | 0.040g |

엔지니어링 문서

규격표 / 도면

AMA10EB045-file.pdf (1185.40KB)

AMA10EB045-file.pdf (1185.40KB)

3D Models

STEP_MA.zip (37.09KB)

STEP_MA.zip (37.09KB)

FAQ

일람All values except for the graph of Junction capacitance vs. Reverse Voltage of SBD products are maximum values, which are guaranteed. Graphs of Junction capacitance vs. Reverse Voltage show typical values (TYP). The curves of the average forward current rating are formed by connecting points where the junction temperature reaches 150℃.

MSL standards are defined for SMDs to be reflow-soldered, and all Kyocera products are MSL: 1. (No need for damp proof packing)

Related Glossary

일람Diodes utilizing potential barrier (schottky barrier) formed at a junction between metal electrode and semiconductor.

Related Products Discretes Schottky Barrier Diodes(SBD) FRD/SBD Modules

[Diode]Allowable peak reverse voltage repetitively applicable to diode.

[Thyristor]Allowable peak reverse voltage repetitively applicable between anode and cathode.

[Diode] Maximum average forward current of commercial frequency (50Hz/60Hz) sin wave under condition.

[Thyristor] Maximum average on-state current of commercial frequency (50Hz/60Hz) half sin wave under specified condition.

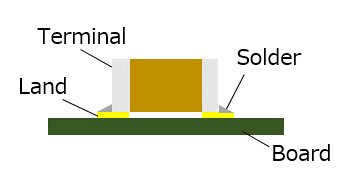

Abbreviation of Surface Mount Technology. A method of producing electronic circuits on a printed circuit board (PCB) by applying solder paste and placing components on the PCB's surface before the solder is melted in a reflow oven.

Range of ambient temperature while not operating.

Stock Check

Stock Check